Fluorite Grinding Ball Mill For Processing

Building a Fluorite Processing Plant: A Comprehensive Guide

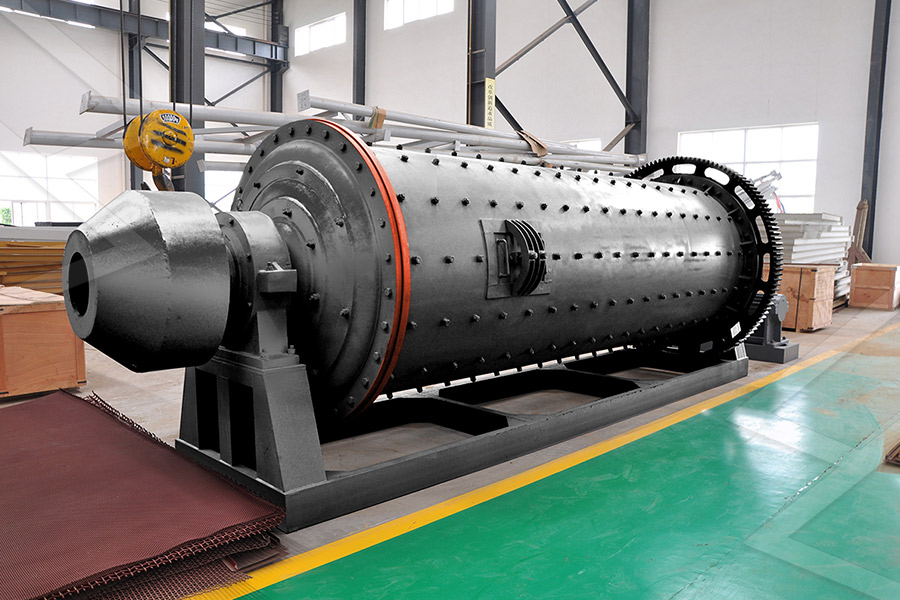

2024年2月28日 Constructing a fluorite processing plant is a multifaceted endeavor that encompasses mineral processing, civil engineering, mine design, and resource exploration This comprehensive guide provides you with the essential steps and considerations for building a 2024年9月7日 Grinding process In the fluorite mineral beneficiation process, large and efficient ball mills are usually used to grind the fluorite ore The ball mill refines the ore to a suitable Fluorite Mineral Processing Flow and Equipment 2023年10月27日 The performance of grinding media in a ball mill is measured in terms of wear rate, which is a function of the media composition, hardness, phase structure, and A Review of the Grinding Media in Ball Mills for Mineral Processing 2023年4月15日 To improve the sintering characteristics of high entropy fluorite oxide ceramics, the oxide mixture was dealt with dielectric barrier discharge plasmaassisted ball milling The The effect of plasmaassisted ball milling on ScienceDirect

Fluorite Processing Equipment, Process Flow,

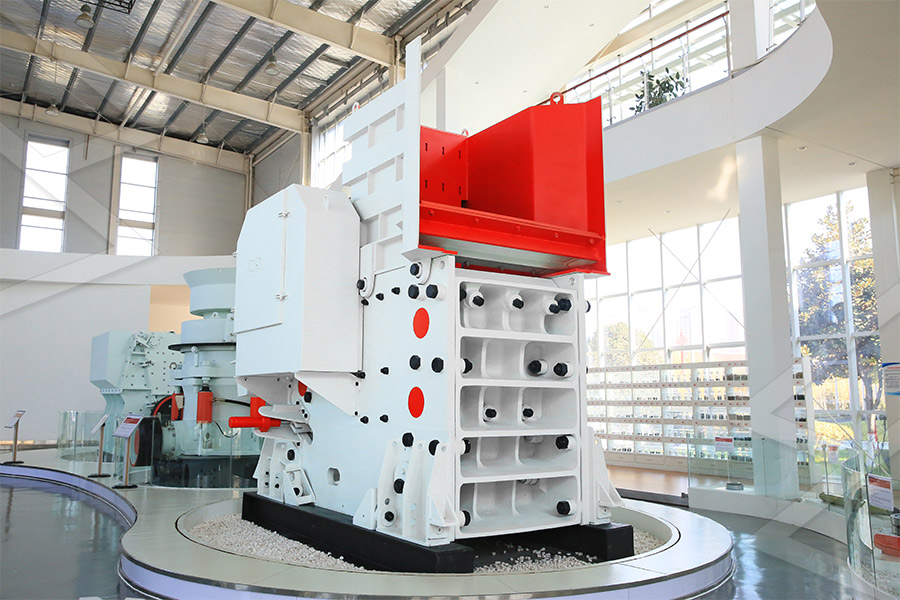

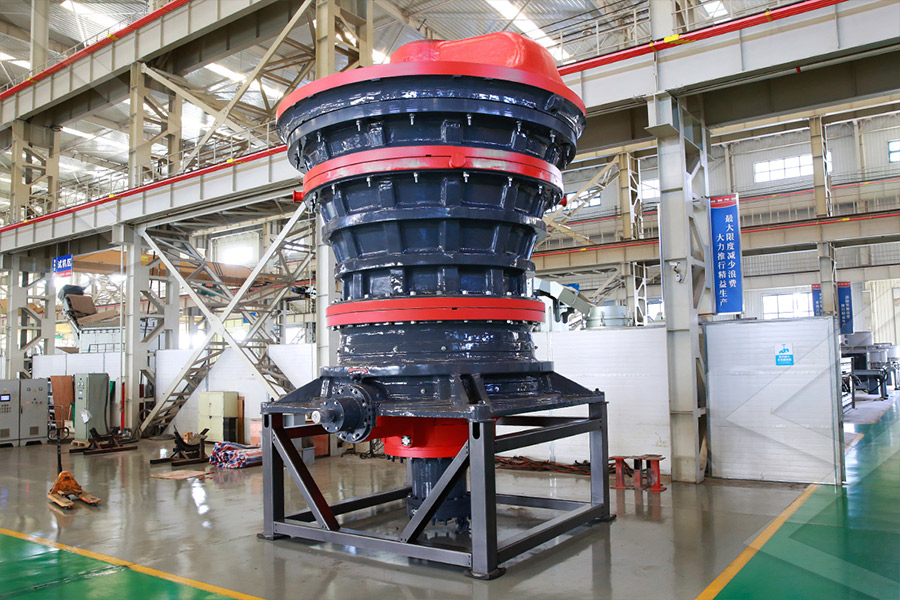

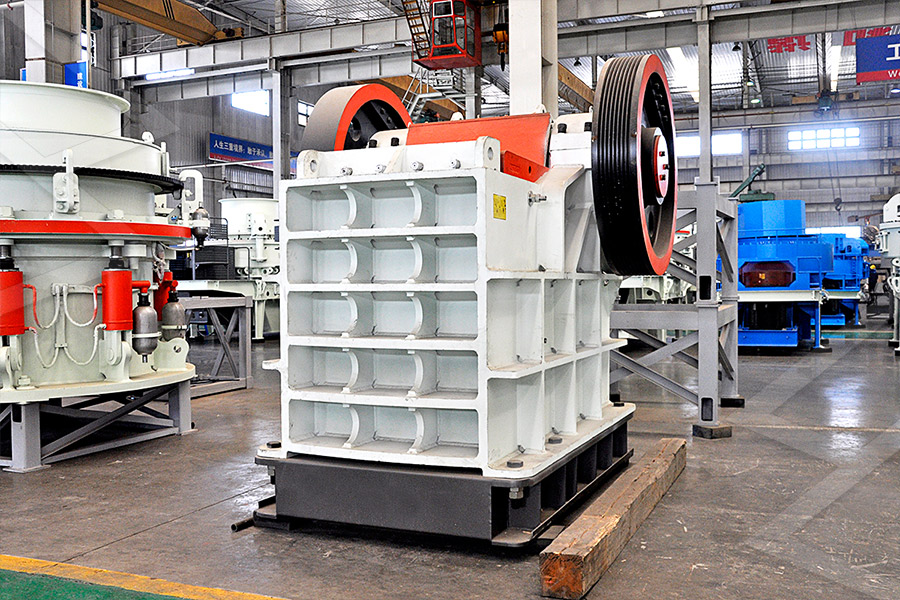

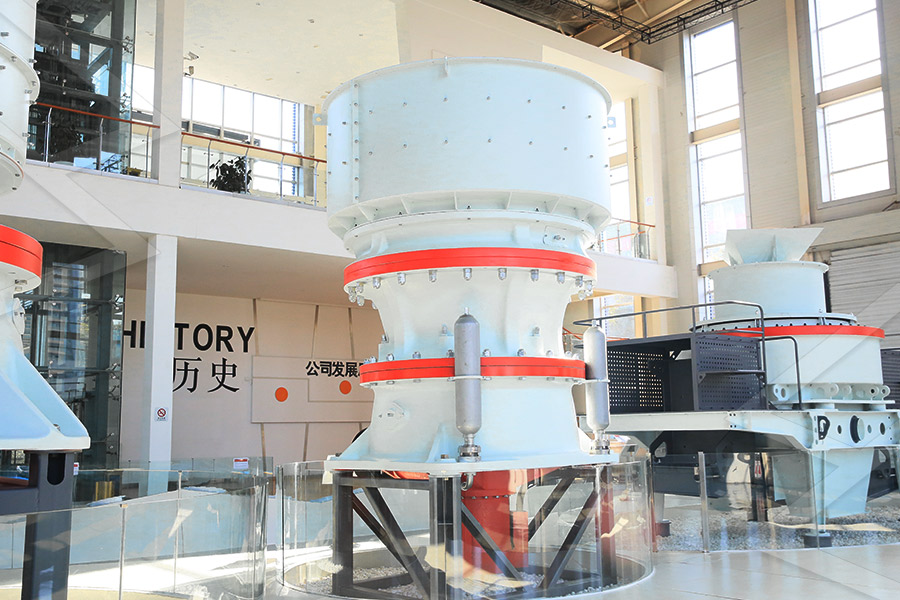

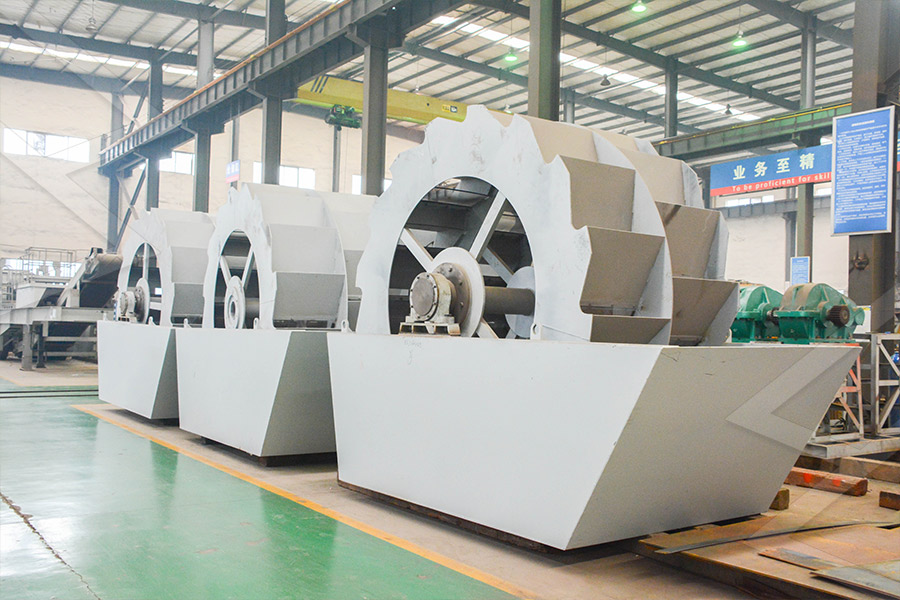

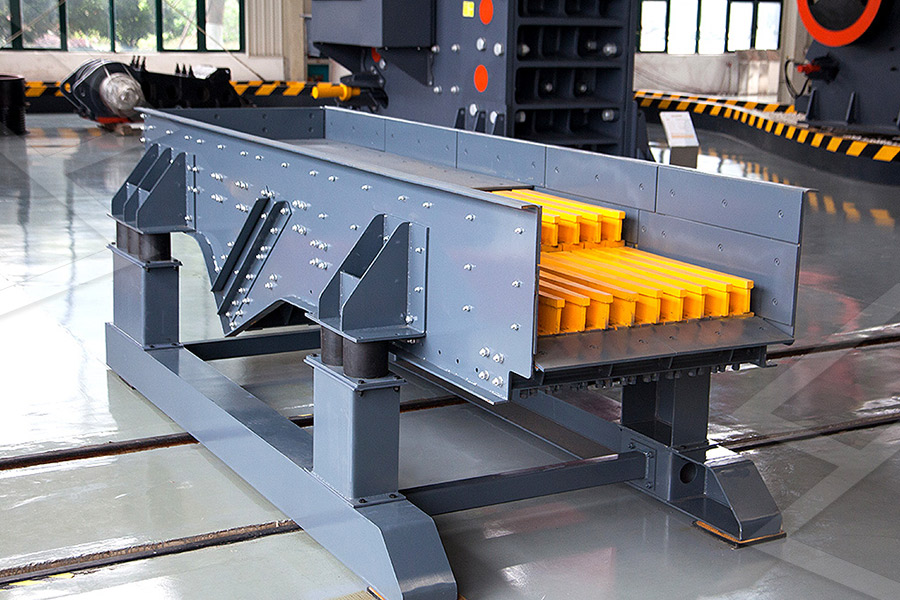

2019年8月23日 Fluorite ore beneficiation process includes crushing, sieving, grinding, grading, flotation, filtration, drying, etc The main beneficiation machines are crusher ( jaw crusher, cone crusher, hammer crusher), vibrating screen, 2021年2月15日 In this study, to enhance the flotation of finegrained fluorite, a strategy that combines simultaneous grinding and surface modification via ballmilling and controlled gas Intensifying finegrained fluorite flotation process with a 2024年6月27日 The ore is first crushed into smaller pieces using jaw crushers or cone crushers The crushed ore is then ground into a fine powder using ball mills or rod mills Grinding the ore helps to liberate the fluorite crystals from the The Ultimate Guide to Fluorspar Processing2024年9月29日 Nowadays, the mineral processing industry is developing rapidly, and the requirements for ball mills that consume large amounts of energy in the mining industry are mqg1564 fluorite ball mill, efficient grinding of fluorite ore

Fluorite Processing Technology and Complete

2023年12月14日 Ball Mill: Artisan of Subtle Refinement Under the influence of the jaw crusher, ore particles become finer, requiring higher precision in the subsequent processes2024年10月18日 Fluorspar mineral processing is a complex field that requires a variety of methods to extract and refine this valuable mineral One common type is gravity separation, which involves separating fluorspar from other minerals Four Common Types Of Fluorspar Mineral Grinding Mill, Raymond Mill, Ball Mill manufacturer / supplier in China, offering Clrm Series Calcium Carbonate Gypsum Limestone Limestone Roller Mill for Sale in Iran, CLUM Series Ultrafine Vertical Roller Mill PE Jaw Crusher with Raymond mill; Superfine grinding mill; Vertical 2023年8月1日 The grinding process of zircon involves choosing the right equipment and achieving the desired particle size When selecting a zircon ball mill, the following factors Fluorite ball mills are widely used in fluorite beneficiation projects to grind fluorite ore into powder, meeting the required specifications for various applications Zircon Ball Mill, Zircon Grinding Process Zoneding Machine

Building a Fluorite Processing Plant: A Comprehensive Guide

2024年2月28日 This includes the capacity, size, material of construction, and any specific features required for the processing of fluorite For example, ball mills need to be specified according to the size of the feed material and the desired product size 2 Vendor Selection4 天之前 Fluorite (Fluorspar) flotation equipment is similar to other mineral flotation equipment including crusher, ball mill, flotation machine, etc 【Application】 Fluorite (Fluorspar) Flotation Process is applied for refractory fluorite with complicated properties such as high mud content, impurity containing, fine particle distribution, etcFluorite Mining Processing Equipment Flow Chart Cases2023年5月27日 In a vertical ball mill, the grinding media is kept in motion by the rotation of the drum, which causes the material to be ground to be crushed between the grinding media and the drum 3) Planetary Ball Mill Planetary ball mills are a type of vertical ball mill that are used in laboratories to grind materials into small particlesBall Milling in Lithium Ore Processing: A Comprehensive Guide2023年7月30日 Fluorite ball mills are widely used in fluorite beneficiation projects to grind fluorite ore into powder, meeting the required specifications for various applications The grinding process achieves a fineness of 200 mesh 706% The coarse concentrate is then returned to the overflow ball mill for regrinding, resulting in a product fineness Fluorite ball mill application in fluorite beneficiation project

Ball Mill Is Indispensable For Lithium Ore Processing

2024年10月18日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common equipment for lithium ore grinding is ball mill Onestage closedcircuit grinding and grading process can be adopted, and the onestage 4 天之前 2 Grinding: The twostage grinding process is usually used in the grinding stage of fluorite mines The ball mill + spiral classifier are combined to form a closedcircuit ring mill, which can be ground to the required particle size 3Fluorite Flotation Process, Equipment JXSC Machinery2 天之前 1 The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, nonmetallic ores, cement clinker, etc 2 It has a highly automated control system, Ball Mill Mining Grinding Mill JXSC Machinery2017年6月9日 As part of its mission to advance minerals technology, the Federal Bureau of Mines has conducted investigations to determine the feasibility of producing subsievesize material by an attrition grinding method The Bureaupatented technique involves the intense agitation of a slurry composed of the material to be ground, a granular grinding medium, and a Attrition Grinding Mill Design 911Metallurgist

What Is Fluorite? Clirik Grinding Mill

Characteristics of fluorite Composition: CaF₂, which contains fluorine 4867%, calcium 5133%, sometimes contain rare elements; often associated with quartz, calcite, barite and metallides2023年7月18日 The grinding media is an important part of the ball mill for grinding ore and needs to be checked for wear If there is wear, it should be replaced in time 2 Check the sieve The sieve is part of the discharge port of the ball mill and needs to be checked for whether the pore is blocked or the sieve is wornBall Mill Maintenance Process and Methods Miningpedia2023年10月20日 A ball mill is a crucial piece of equipment used for grinding and blending materials, commonly utilized in mineral processing, ceramics, and pyrotechnics industries Understanding the principles of operation and best practices for efficient and safe operation is essential for achieving optimal performance and minimizing prehensive Guide on Operating a Ball Mill Miningpedia2 Grinding: The twostage grinding process is usually used in the grinding stage of fluorite mines The ball mill + spiral classifier are combined to form a closedcircuit ring mill, which can be ground to the required particle size 3Fluorite Processing Zoneding Mining Machine

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy models of the grinding 2024年10月18日 Ball Mill is a type of grinder used to grind materials into an extremely fine powder mainly for use in the mineral processing industry Ball Mills can grind various ores and other materials either wet or dry, depending on requirementsHigh Energy Saving Fluorite Graphite Barite Power Ball Mill Grinding 2024年8月7日 01 Fixed factors affecting ball mill The factors that are relatively fixed and do not need to be adjusted frequently in ball mill operation include the hardness of the original ore, the size of the crushed particle size, the mesh of the grid screen, the model of the ball mill, the quality of the steel ball, the amount of steel ball added, the ratio of the size of the steel ball, the speed Ball Mill Operation, Maintenance and Common Problems 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for

Fluorite Fine Powder Grinding Mill SBM Ultrafine Powder

2021年10月13日 Fluorite Fine Powder Grinding Mill >> The application of fluorite powder in various fields has different fineness requirements Common ones are 100 mesh, 200 mesh, 325 mesh, 600 mesh, 800 mesh, 1250 mesh, and above According to different needs, the most suitable grinding mill machine can be configured to achieve the best benefits2022年5月19日 The grinding operation of rock gold mine usually adopts onestage or grid ball mill + overflow ball mill for twostage grinding The second stage grinding operation forms a closed loop with a spiral classifier or a How to Process Gold Ore? 4 Gold Processing 2023年9月21日 02 Grinding media size on ball mill grinding Proper media size affects the quality of the grinding product During the coarse grinding process, the grinding medium makes a throwing motion, which impacts the material Therefore, it is necessary to select a larger size medium during coarse grindingHow Many Factors Affect Grinding Efficiency of Ball Mill?2024年7月12日 Grinding Media Size and Weight: The size and weight of the grinding media can dramatically influence the milling action Balls made of more dense media can produce a coarse grind, while lighter balls lead to a finer grind The choice of media depends on the material being milled and the desired particle sizeWalking Through the Ball Milling Process Economy Ball Mill

Dry Ball Mill VS Wet Ball Mill: What Are the Differences

2020年11月13日 1) Structure The shape and components of the wet ball mill and the dry ball mill are basically the same The barrel is cylindrical, and the structure mainly includes the feeding part, the discharging part, the rotating part, the transmission part (reducer, small transmission gear, motor, electric control), etc2023年10月1日 Also, knowing more about grinding by developing simple prediction methods will aid in the grinding process's design, scaleup, and optimization, including for the new design mills The Bond ball mill work index test is a standard procedure to determine the ore grindability in function of specific energy (kWh/ton)Estimation methodology for Bond ball mill work index 2024年9月7日 When selecting a ball mill, its processing capacity and energy efficiency need to be considered to ensure the efficiency and economy of the grinding process A suitable ball mill can not only improve the grinding efficiency, but also effectively reduce energy consumption, thereby improving the costeffectiveness of the entire fluorite Fluorite Mineral Processing Flow and Equipment 2023年12月28日 Therefore, choosing the appropriate product fineness is also essential in improving the production and quality of ball mills 6 Grinding process For ball mills of the exact specifications, the output of the closedcircuit process is 15 to 20% higher than that of the opencircuit process During closedcircuit operation, choosing the Factors Affect The Output and Quality of Ball Mills And How

Fluorite Beneficiation Process JXSC Mineral

3 天之前 The fluorite gravity separation process Crushing and Grinding The raw fluorite ore is first crushed into small particles to liberate fluorite crystals from the gangue mineralsThe crushed ore is then ground to achieve a finer size for efficient separation Washing and Screening2024年10月18日 Fluorspar mineral processing is a complex field that requires a variety of methods to extract and refine this valuable mineral One common type is gravity separation, which involves separating fluorspar from other minerals Four Common Types Of Fluorspar Mineral Grinding Mill, Raymond Mill, Ball Mill manufacturer / supplier in China, offering Clrm Series Calcium Carbonate Gypsum Limestone Limestone Roller Mill for Sale in Iran, CLUM Series Ultrafine Vertical Roller Mill PE Jaw Crusher with Raymond mill; Superfine grinding mill; Vertical 2023年8月1日 The grinding process of zircon involves choosing the right equipment and achieving the desired particle size When selecting a zircon ball mill, the following factors Fluorite ball mills are widely used in fluorite beneficiation projects to grind fluorite ore into powder, meeting the required specifications for various applications Zircon Ball Mill, Zircon Grinding Process Zoneding Machine

Building a Fluorite Processing Plant: A Comprehensive Guide

2024年2月28日 This includes the capacity, size, material of construction, and any specific features required for the processing of fluorite For example, ball mills need to be specified according to the size of the feed material and the desired product size 2 Vendor Selection4 天之前 Fluorite (Fluorspar) flotation equipment is similar to other mineral flotation equipment including crusher, ball mill, flotation machine, etc 【Application】 Fluorite (Fluorspar) Flotation Process is applied for refractory fluorite with complicated properties such as high mud content, impurity containing, fine particle distribution, etcFluorite Mining Processing Equipment Flow Chart Cases2023年5月27日 In a vertical ball mill, the grinding media is kept in motion by the rotation of the drum, which causes the material to be ground to be crushed between the grinding media and the drum 3) Planetary Ball Mill Planetary ball mills are a type of vertical ball mill that are used in laboratories to grind materials into small particlesBall Milling in Lithium Ore Processing: A Comprehensive Guide2023年7月30日 Fluorite ball mills are widely used in fluorite beneficiation projects to grind fluorite ore into powder, meeting the required specifications for various applications The grinding process achieves a fineness of 200 mesh 706% The coarse concentrate is then returned to the overflow ball mill for regrinding, resulting in a product fineness Fluorite ball mill application in fluorite beneficiation project

Ball Mill Is Indispensable For Lithium Ore Processing

2024年10月18日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common equipment for lithium ore grinding is ball mill Onestage closedcircuit grinding and grading process can be adopted, and the onestage 4 天之前 2 Grinding: The twostage grinding process is usually used in the grinding stage of fluorite mines The ball mill + spiral classifier are combined to form a closedcircuit ring mill, which can be ground to the required particle size 3Fluorite Flotation Process, Equipment JXSC Machinery